About Us

Founded in 1985, JDONG Group is headquartered in the Qingdao Automotive Industry New City, with over 550 employees. The Qingdao headquarters consists of three production plants, covering a total area of 150,000 square meters, including 80,000 square meters of workshop space.

After 40 years of development, the company has become a comprehensive commercial vehicle parts group integrating R&D, manufacturing, and supporting services. It is a first tier supplier to 24 OEMs, including FAW, DFAC, CHERY, SINOTRUCK, SHACMAN, BAIC, JAC, JMC,etc. Its products and solutions span across medium and heavy trucks, light trucks, pickups, and passenger vehicles,making it a leading automotive parts supplier in the automotive industry.

In the domestic medium- and heavy-duty truck OEM segment, the company is the undisputed leader in commercial-vehicle rearview mirrors, capturing over 40 % of the market for seven consecutive years and firmly maintaining its industry-leading position. Its rapidly expanding vehicle-camera portfolio already ranks among the top three in China.

The Company will continue to carry forward the business development policy of “Keep Your Eyes on the Sters, and Your Feet on the Ground”, fully leverage its external and internal advantages, and explore broader growth opportunities. In the future, Committed to Becoming China’s First and World-class Automotive Visual System Supplie

Headquartered in the Qingdao Automotive Industry New City, the group covers a total area of 150,000 square meters, with 80,000 square meters of built-up area.

- Recognized as a Tier 1 supplier by 24 OEMs.

- In the medium and heavy truck segment, the top 5 OEMs (FAW、DFM、Sinotruk、Shacman、FOTON ) account for over 85% of the market — all are core customers of Jidong,

affirming its industry leadership. - In the light truck segment, focusing on pickups and high-end light trucks, Jidong is a core supplier to Foton,JMC,Sinotruk, FAW , Weichai Power.

- In the passenger vehicle segment, JDONG is steadily expanding and is a core supplier to CHERY , JMC , Ford and others</li>

- National High-tech Enterprise

- National Specialized, Refined, Unique and New “Little Giant” Demonstration Enterprise

- CNAS National Laboratory

- Shandong Technology Center

- Technology Little Giant Enterprise

Industrial Layout

In the domestic medium- and heavy-duty truck OEM segment, Jidong has captured over 40 % of the mirror market for seven consecutive years, selling and producing 394,000 units in 2024 for a 43.3 % domestic share.

Platform based design, we offer 300+ mirror solutions covering sedans, SUVs, pickups and light vans.

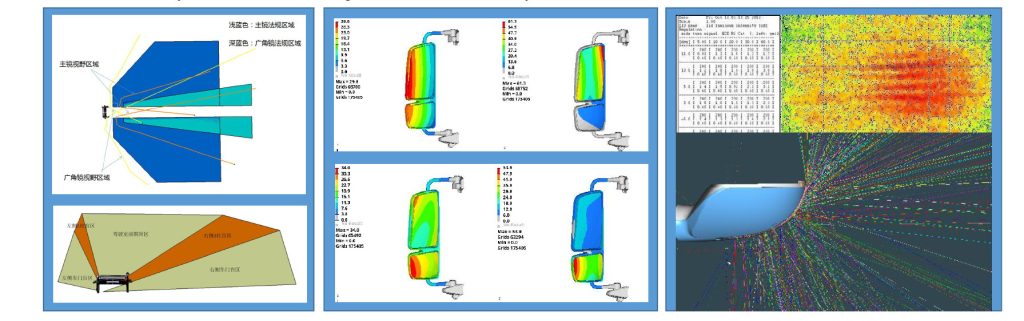

R&D Capability

Technical Team

- 6 expert team members

- 5 staff with senior professional titles

- 79 engineers

- 88% for undergraduates

- 28% for graduates from 985/211 universities

- 15% for postgraduates

Industry –University -Research Cooperation

- Professor Song Jian Team, Tsinghua University

- Dr. Li Xingkun Team, Tsinghua University

- College of Automotive Engineering, Jilin University

- School of Automotive Engineering, Wuhan University of

Technology

Hundreds of product developments have built a comprehensive design library that is managed on shared platforms, ensuring high performance while keeping costs optimized.

Follows a three-generation R&D strategy: “Produce one generation, reserve one, develop one” to ensure continuous innovation and technological leadership.

Quality Management

- CNAS National Laboratory Accreditation

- Approved laboratories by multiple major engine manufacturers such as FAW, DFM, JAC, Foton and Shacman.

- 100 inspection and testing equipment, capable of completing over 2010 inspection and testing projects, including environmental testing,

performance testing, dimensional inspection, optical testing, and other proprietary tests for products such as rearview mirrors and electronic products; - Capable of completing all national and European standard testing projects for rearview mirrors, it is one of the most comprehensive rearview mirror

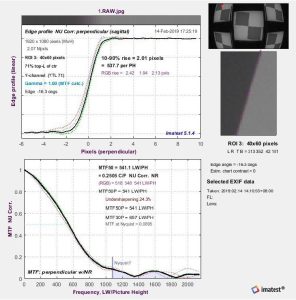

laboratories in China; - The optical laboratory is equipped with IMATEST professional analysis software, which can test and evaluate 16 vehicle electronic imaging projects such as

image resolution, color reproduction, brightness uniformity, etc; - The largest and most advanced comprehensive wind tunnel laboratory for radiators in China.

• High temperature test chamber

• IP9Xspray test chamber

• Cold and hot alternating test chamber

• Mechanical impact test bench

• Constant temperature and humidity chamber

• Electrostatic generator

• Key life testing machine

• Oscilloscope

• Double arm drop testing machine

Key optical-testing equipmen

Image Test software

Capable of evaluating resolution, color fidelity, luminance uniformity, color uniformity, white balance, grayscale, SNR, distortion, field of view, stray light, ghosting, sensitivity, and scene rendition.

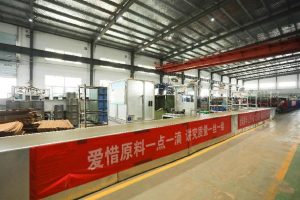

Manufacturing Capability

- Ten thousand level dust-free workshop.

- Manufacturing capability of the entire electronic imaging industry chain: SurfaceMountTechnology, Active Alignment, FG assembly, online aging.

- Automatic testing of the entire process including image, electrical, dirt, airtightness, aging, etc., with full parameter self-control capability.